Sometimes I'll refer to the ESC as a servo, as that's how it needs to be treated electronically. The adapter serves three purposes:

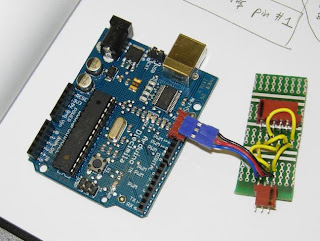

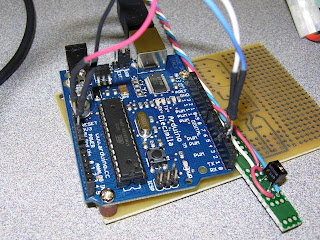

- Connects the signal wires from each servo to digital output pins on the Arduino.

- Connects the Arduino's ground pin to both servo ground wires. The ground must be common, or none of the signalling will work.

- Connects the steering servo's 6V supply to the ESC's 6V line, to provide power. This doesn't connect to the Arduino at all.

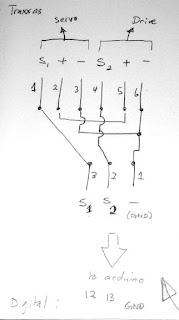

Here's the wiring diagram:

S1 and S2 are the signal lines, going to digital pins 12 and 13 on the Arduino, respectively. Digital pin 13 also happens to control the built-in LED indicator, which flickers now when that signal is sent. The ground is common, of course. The servo lines therefore plug directly into the adapter board, so it can replace the radio receiver.

Using the Servo.h library for Arduino, it's relatively easy to control the steering servo: you specify a position between 0 and 180 degrees, and call refresh at least once every 20ms, and the servo will move. The servo doesn't need its full range of motion, as the steering links don't have that much travel. Moving the servo between 40 and 140 degrees is enough to fully articulate the steering: any more and you can hear the servo grinding and the servo saver stressing.

Unfortunately the ESC is another story. So far no signal I've sent it has elicited any response. I'll have to find some documentation on how that one works.

The servo code is based on the tutorial on the Arduino Playground. Here it is:

#include

#define pin1 12

#define pin2 13

Servo servo1;

Servo servo2;

int angle = 90;

int dir = 1;

int counter = 0;

int counterMax = 100;

void setup()

{

servo1.attach(pin2);

Serial.begin(9600);

Serial.print("Ready");

}

void loop()

{

static int v = 0;

if(counter > counterMax)

{

counter = 0;

angle = angle + dir;

if(angle > 140){dir = -1;}

if(angle < dir =" 1;} servo1.write(angle);

Serial.print("angle: ");

Serial.println(angle);

}

counter++;

Servo::refresh();

}

Unfortunately the ESC is another story. So far no signal I've sent it has elicited any response. I'll have to find some documentation on how that one works.

The servo code is based on the tutorial on the Arduino Playground. Here it is:

#include

#define pin1 12

#define pin2 13

Servo servo1;

Servo servo2;

int angle = 90;

int dir = 1;

int counter = 0;

int counterMax = 100;

void setup()

{

servo1.attach(pin2);

Serial.begin(9600);

Serial.print("Ready");

}

void loop()

{

static int v = 0;

if(counter > counterMax)

{

counter = 0;

angle = angle + dir;

if(angle > 140){dir = -1;}

if(angle < dir =" 1;} servo1.write(angle);

Serial.print("angle: ");

Serial.println(angle);

}

counter++;

Servo::refresh();

}

Note that you need to download the Servo.h code, which is available through the tutorial linked earlier. Anyway, here's a video of the Arduino running the steering: